HOT SALE

APPLICATION

Contact:Whatsapp:8618268932884 Email:helen.cf@changfatextile.com

Heat transfer printing is a new printing technology, which has been introduced from abroad for more than 10 years. This printing process is divided into two major parts: transfer film printing and transfer processing. Transfer film printing adopts dot printing to print patterns on the film surface in advance.

The printed patterns have rich layers, bright colors, and infinite varieties, with small color difference and good reproducibility, which can meet the requirements of designers and is suitable for mass production. Transfer processing transfers the beautiful patterns on the transfer film to the surface of the product through a heat transfer printing machine, and after molding, the ink layer and the product surface merge into one, which is realistic and beautiful, greatly improving the grade of the product. However, due to the high technical content of this process, many materials need to be imported.

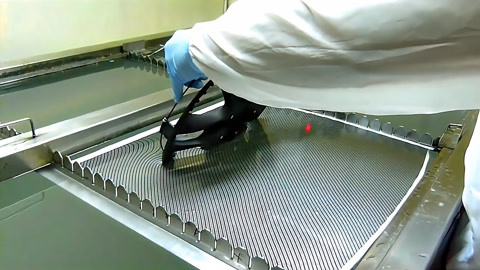

Water transfer printing dissolves and transfers the stripping layer on the water transfer printing carrier film by using water pressure and activator.

Heat transfer printing is a technology that prints patterns on heat sublimation paper and then transfers the ink layer patterns to the finished material through heating and pressing. It can shorten the printing time, reduce material losses caused by printing errors, and print realistic patterns. heat transfer printing technology is widely used in textiles, daily necessities, etc. Because of its corrosion resistance, wear resistance, and color retention for 15 years, it can stand the test of time, with long-term shape retention and color fastness. It cannot be worn out by contact with solvents, nor deformed or discolored by high temperatures. Generally, inkjet and laser printing technologies cannot achieve such effects.

There are two types of water transfer printing technologies, one is water mark transfer printing technology, and the other is water casting transfer printing technology.

The former mainly completes the transfer printing of texts and realistic patterns, while the latter tends to carry out complete transfer printing on the entire product surface. Casting transfer printing technology can cover color patterns on workpieces of any shape, solving the problem of three-dimensional product printing for manufacturers.

The curved surface coating can also add different textures to the product surface, such as leather texture, wood grain, jade texture and marble texture, while avoiding the virtual position often seen in general plate printing. In the printing process, since the product surface does not need to contact the printing film, it can avoid damaging the product surface and its integrity.