HOT SALE

APPLICATION

Contact:Whatsapp:8618268932884 Email:helen.cf@changfatextile.com

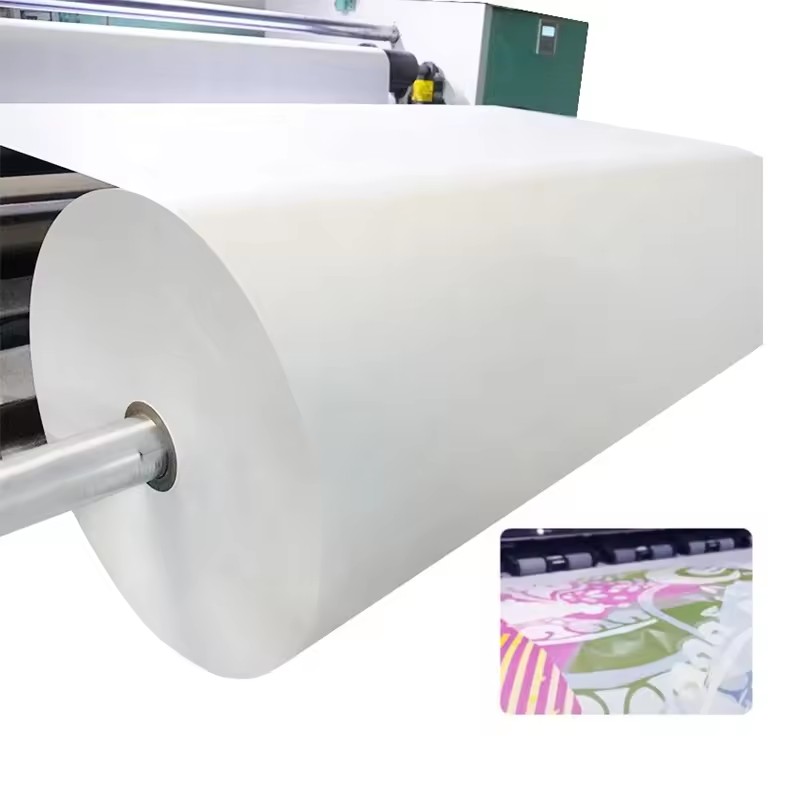

The high-precision spray printing process of digital printing fabric enables the printing process to be water and color paste free.

The use of dyes in the process of spray printing is “allocated on demand” by the computer, which ensures that there is no waste of dyes and chemicals and no wastewater generated in the process of spray printing. During the spray printing process controlled by the computer, no noise is produced, ensuring that there is no pollution in the process of spray printing. This has realized the green production process, thereby enabling the textile printing and dyeing production to be freed from the high energy consumption, high pollution, and high noise production process in the past. It has achieved a low-energy and pollution-free production process, bringing a technological revolution to the production of textile printing and dyeing.

Digital printing fabrics (cloth) production has truly achieved the small-batch and fast-response production process, with the production batch size being unrestricted.

Since the digital printing production process is fully computerized and digitalized, the flexibility of production is greatly improved. Some products can even be delivered on the same day and ready for pick-up immediately.

The main products of digital printing fabrics include: digital printing sampling and small-batch production of various types of clothing fabrics, home textile fabrics, knitted fabrics, glasses cleaning cloths, advertising banners, and personalized fabric products. It can print both traditional printing patterns and modern and fashionable color photos.

Digital printing for knitted fabrics: adopting the guided belt digital printing process, it can print knitted fabrics, lightweight fabrics, and elastic fabrics without deformation or wrinkling.