HOT SALE

APPLICATION

Contact:Whatsapp:8618268932884 Email:helen.cf@changfatextile.com

1.Different Nature

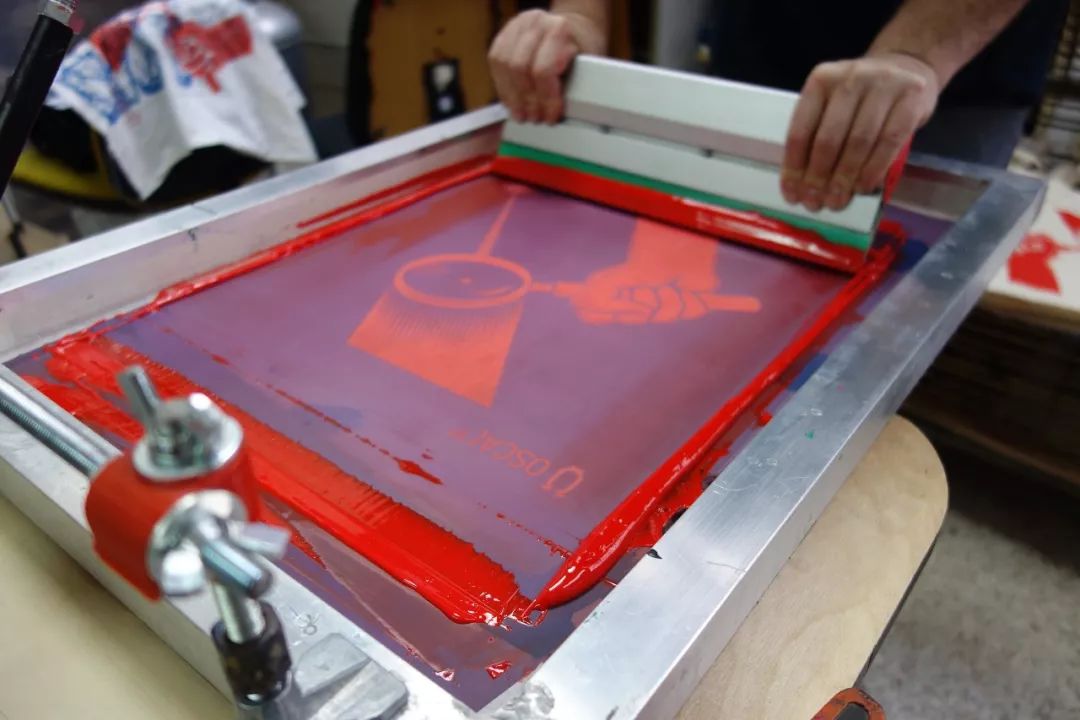

(1) Silk Screen Printing

Silk screen printing is the abbreviation of “silk screen printing”. It tensions silk fabric, synthetic fiber fabric or metal wire mesh on a mesh frame, and uses the method of hand-carved paint film or photochemical plate making to make a screen printing plate. Modern screen printing technology uses photosensitive materials to make screen printing plates by photolithography.

(2) Heat transfer

Heat transfer is a new method of printing patterns on various materials, especially suitable for creating a small number of diverse personalized and customized products, as well as printing patterns containing full-color images or photos. The printing process is divided into two parts: transfer film printing and transfer processing. Transfer film printing adopts dot printing, which prints patterns on the surface of the film in advance. The printed patterns are rich in layers, bright in color, and varied. The color difference is small, and the reproducibility is good, which can achieve the desired effect of the designer, and is suitable for mass production.

2.Different Principles

(1)Silk screen printing

The basic principle of silk screen printing is to print by utilizing the basic principle that the mesh of the image and text part of the screen allows ink to pass through, while the mesh of the non-image and text part is impervious to ink. During printing, ink is poured into one end of the screen plate, and a squeegee is used to apply a certain amount of pressure on the inked area of the screen plate while moving towards the other end of the screen plate. The ink is squeezed from the mesh of the image and text part onto the substrate by the squeegee during movement.

(2)Heat transfer printing

The principle is to print digital patterns on transfer paper with special transfer ink through a printer, and then accurately transfer the patterns to the surface of the product with high temperature and high pressure using a special transfer machine, thus completing the product printing.