HOT SALE

APPLICATION

Contact:Whatsapp:8618268932884 Email:helen.cf@changfatextile.com

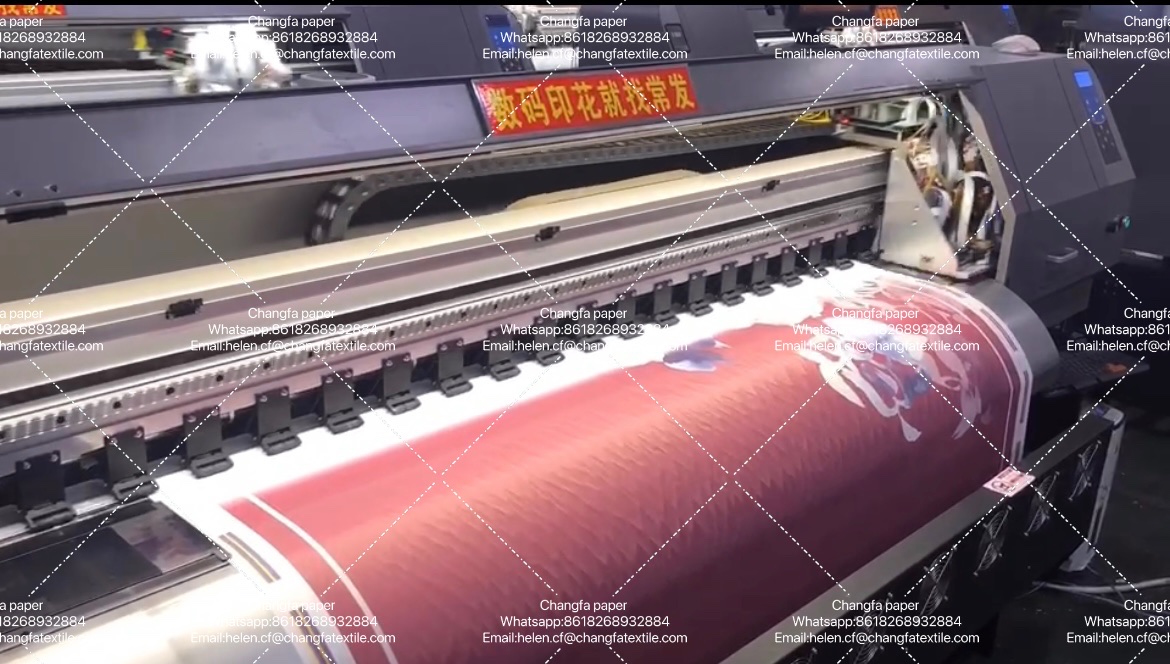

The special heat transfer ink is used to print various patterns on a special kind of paper, and then the patterns are transferred to the product through temperature and pressure.

This special paper in the heat transfer printing process is called heat transfer paper. Transfer printing refers to the printing process of transferring dyes to fabrics through transfer paper. It is based on the sublimation characteristics of some disperse dyes, and selects disperse dyes that sublime at 150~230°C. The dyes are mixed with slurry to make ink, and then printed on transfer paper according to different design pattern requirements (this is a specially made paper, so it is called transfer paper).

Then the transfer paper printed with patterns is closely contacted with the fabric, and under the control of certain temperature, pressure and time, it enters the interior of the fabric through diffusion, so as to achieve the purpose of coloring.

Inkjet printing paper is mainly used for inkjet printers. This type of inkjet printing paper, a high-end commercial paper, features fast ink absorption, no ink drop diffusion, high printing density, continuous tones, clear images, good preservation, certain water resistance, light resistance, and strong and durable coatings. The coatings are also scratch-resistant, non-static, smooth, flexible, and foldable.

This type of high-end commercial paper is a new type of recording paper, so it is generally produced according to national standards. Its quality is not inferior to similar foreign products and has strong market competitiveness.

Inkjet printing paper differs greatly from ordinary paper. This is because color inkjet printing usually uses water-based ink, and ordinary paper quickly absorbs and spreads the ink, resulting in substandard printing quality in both color and clarity.

Inkjet printing paper is a product of deep paper processing. It is created by applying a special coating to the surface of ordinary printing paper to enable it to absorb water-based ink while preventing ink droplets from spreading, thus preserving the original color and clarity.

Only printing paper weighing 60 to 180 grams can meet the requirements. Ultra-thin printing paper weighing less than 60 grams is prone to multiple sheets feeding into the printer at the same time.