| Device model | CF-6000 | |

| Sprinkler | Nozzle type | 6*Epson 5113 |

| Number of nozzles | 6 pcs | |

| Nozzle attributes | Automatic cleaning, automatic flash spray moisturizing function | |

| Printing speed | 1pass 200㎡/h | |

| 2pass 110㎡/h | ||

| 3pass 75㎡/h | ||

| Ink | Color scheme | C M Y K |

| Ink type | Sublimation ink | |

| Ink supply method | Siphon ink supply | |

| Effective width | 1800mm | |

| Print media | Sublimation paper | |

| Media transfer | Dual power direct collection | |

| Drying method | External intelligent air-heat integrated dryer | |

| Moisturizing mode | Fully sealed automatic moisturizing and cleaning | |

| RIP software | Support Maintop6.1, photoprint, ONYX, NeoStampa and other software, standard Maintop6.1 | |

| Support image format | JPG, TIF, PDF, etc. | |

| Computer setup | Operating system | Win7 64bit / Win10 64bit |

| Hardware requirements | Hard disk: 500G or more (solid state drive is recommended), running memory 8G, graphics card: ATI independent display 4G memory, CPU: Intel quad-core i5/i7 processor | |

| Transmission interface | Gigabit Ethernet | |

| Standard configuration | Tension delivery system, intelligent drying system, liquid level alarm system | |

| Working environment | Humidity: 15%-25% Temperature: 40-60 degrees | |

| Power requirement | Input voltage | 210-230VAC 50/60 HZ 10A |

| Printing system | 1000W | |

| Drying system | Maximum power: 3000W | |

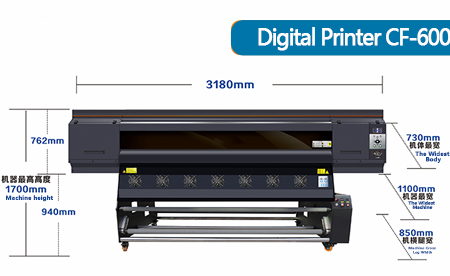

| Machine size | Physical dimension | 3180*1700*1500mm |

CATALOGS

APPLICATION

Type:CF-6000

Ink Type: C M Y K

Max Print Width: 1900 mm

Printing Speed: 1 PASS:200㎡/h; 2 PASS: 110㎡/h; 3 PASS: 75㎡/h

Product Description

Digital Printer CF-6000

![]() Size data

Size data

![]() Functions and features:

Functions and features:

1. The secondary ink supply system is adopted to keep printing for a long time to ensure the output quality of the picture

2. Adopting international high-end software, the pictures are more realistic and the reproducibility is better.

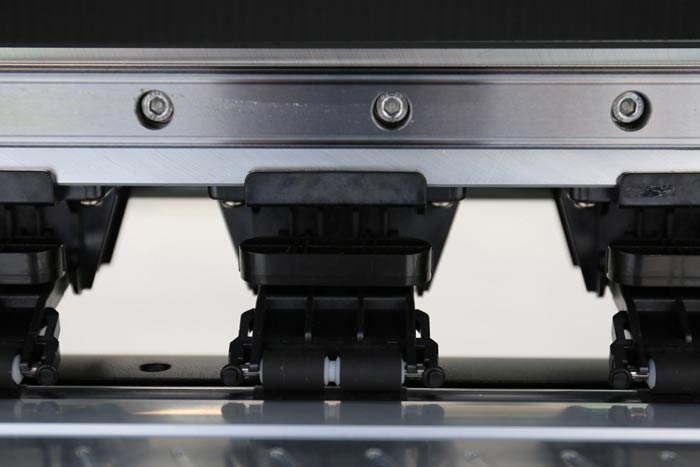

3. Anti-collision frame: The position of the nozzle can be adjusted according to different printing consumables. Anti-collision devices are added at both ends to provide more comprehensive safety protection for the nozzle.

4. Intelligent alarm for lack of ink: Intelligent reminder of lack of ink reduces the cumbersomeness of frequently checking the remaining amount of ink. At the same time, it reminds to add ink in time to ensure the continuity of printing work.

5. Ink stack: equipped with advanced intelligent nozzle cleaning and moisturizing device, providing safe and convenient nozzle cleaning and maintenance functions, operation and maintenance are more convenient.

6. Adopting Japanese THK silent linear guide rail, the movement is more stable and the service life is longer

7. The American fluorine rubber press roller can prevent static electricity from flying and ink, print size more accurately, and reject wrinkles.

8. Two-way Lexai brushless motor, high-precision drive linear decoding, higher precision, smaller length error, and more stable performance.

9. Two-stage continuous ink supply system: continuous printing for a long time; four super-capacity ink cartridges, each ink tube independently supplies ink for a row of nozzles, ensuring high-speed output of large-area thick images.

10. The standard computer host, monitor, keyboard and mouse bracket, eliminating the cumbersome purchase of a computer desk separately, the workshop layout is more concise

Advantage

-

01

Adopting international high-end software

-

02

Anti-collision frame

-

03

Intelligent alarm for lack of ink

-

04

Ink stack

parameter

Production Process

We can provide all types of machines, and the price is very advantageous.